Advantages of Collated Screws

-

Increased Construction Productivity

Using these screws assists workers in completing tasks speedily by automating the process of feeding and driving screws. The users can finish the work smoothly, increasing productivity on the job site. Collated screws offer time savings in large-scale projects, greatly enhancing the speed of tasks like drywall installation, decking, and subflooring.

-

Easy Accessibility

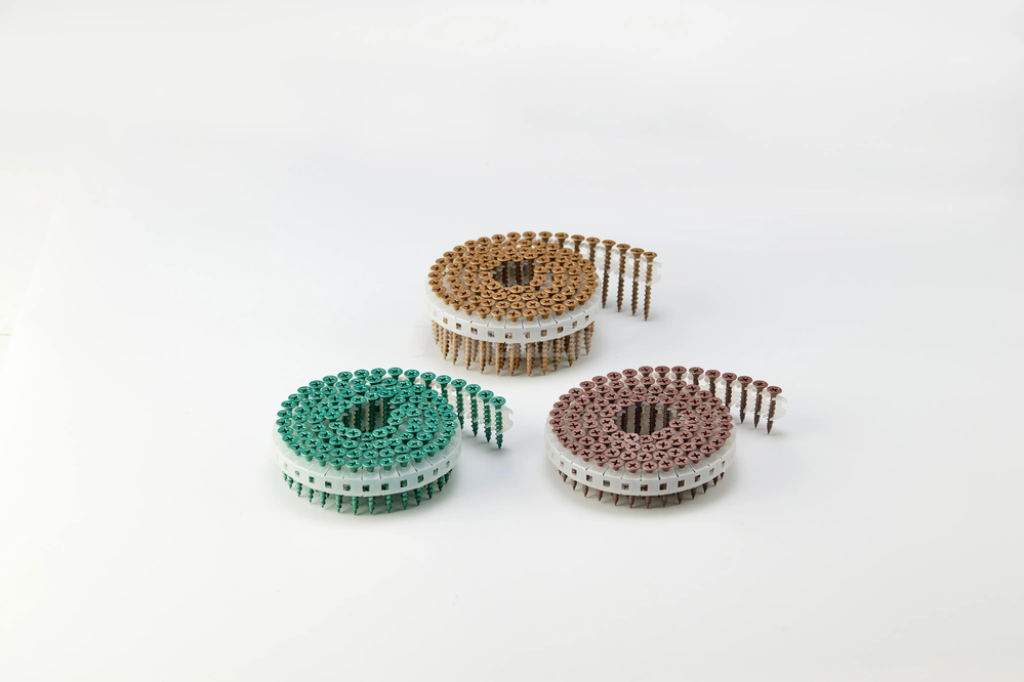

Collated screws are pre-loaded on strips or coils for quick feeding into auto-feed screw guns, eliminating the need for manual placement and speeding up the process. Thus, it simplifies the process. This is beneficial for big projects that need a lot of screws.

-

Time Savings

Using an auto-feed screw gun, workers can drive multiple screws in rapid succession without having to reload after each one. Auto-feed screw guns ensure that each collated screw is driven with consistent pressure and depth. By reducing the need for repetitive motions, such as bending down to pick up screws or manually positioning them, collated screws prevent fatigue and repetitive strain injuries. This allows workers to maintain a steady pace for more extended periods. By using these screws, businesses can save time and money on screwing tasks.

-

Improved Installation Correctness and Neatness

Manual handling of individual screws can lead to errors such as misalignment or inconsistent driving depth. Collated screws minimize these errors by automating the feeding and driving process, which enhances overall installation quality. They can be put in straight and at the same depth. The finished project is stronger and looks better.

-

Flexibility

Available in various lengths, diameters, metal types, and thread types, collated screws cater to many materials, including drywall, wood, and metal.