Types of Collated Screws

They come in many configurations to match diverse auto-feed screw gun systems:

1. Belt-Type Collated Screws

Screws are connected by a flexible plastic belt. The belt feeds smoothly through the tool, allowing for quick firing. The belt design ensures that screws can be fired in rapid succession, lowering downtime and increasing productivity.

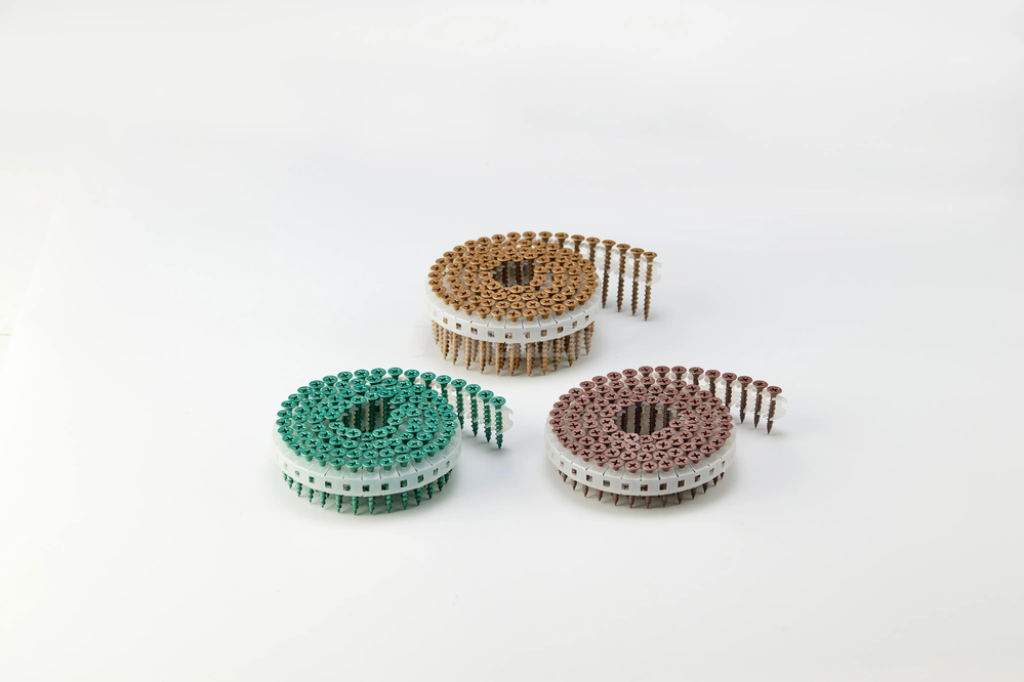

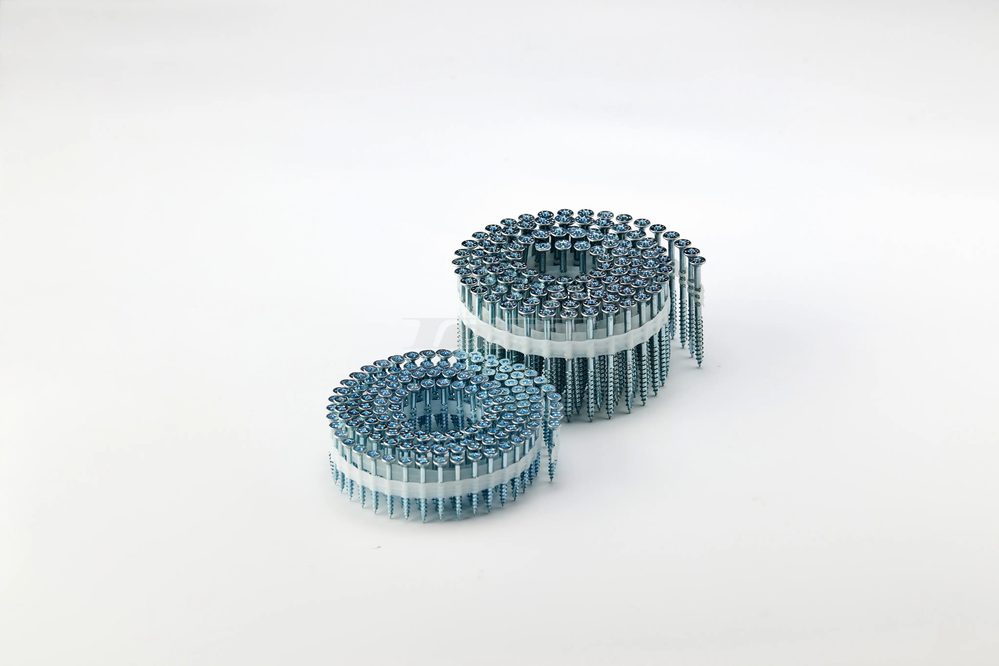

2. Coil-Type Collated Screws

These screws are arranged in a coil format, excellent for high-volume applications where a large number of screws are needed without frequent reloading. Coil-type collated screws can hold many more screws in a single coil compared to other types. The coil format reduces the bulkiness of screw storage, providing workers with a highly portable option for fastening.

3. Strip-Type Collated Screws

Screws are attached to a rigid plastic strip, providing stability and convenience. Strip-type prevents jamming and offers consistent screw delivery. Commonly used in general construction, woodworking, and light framing where reliable, jam-free performance is required. This type is useful for installing drywall, siding, and wooden structures.

While the collated strips differ in design, they are tailored to fit specific screw gun systems. Choosing the proper type is essential for compatibility and optimal performance. For specialized screw specifications—such as unique head shapes, materials, or thread types—consulting with a manufacturer like K. TICHO Industries can provide customized solutions to meet customer’s needs.