Types of Nail Collators

There are three primary types of nail collators, each suitable for different applications based on how the nails are connected.

1. Wire Coil Nail Collator

The wire coil nail collator connects each nail using wire and forms a coil through electrical welding. This method provides a stable, dependable connection for heavy-duty applications. The wire coil design keeps the coil nails tightly connected, even under heavy usage.

- Applications: Commonly used in the production of wooden pallets, floorboards, and heavy-duty wooden structures, wire coil nails are particularly suited for industrial and construction projects needing high-strength wood joining.

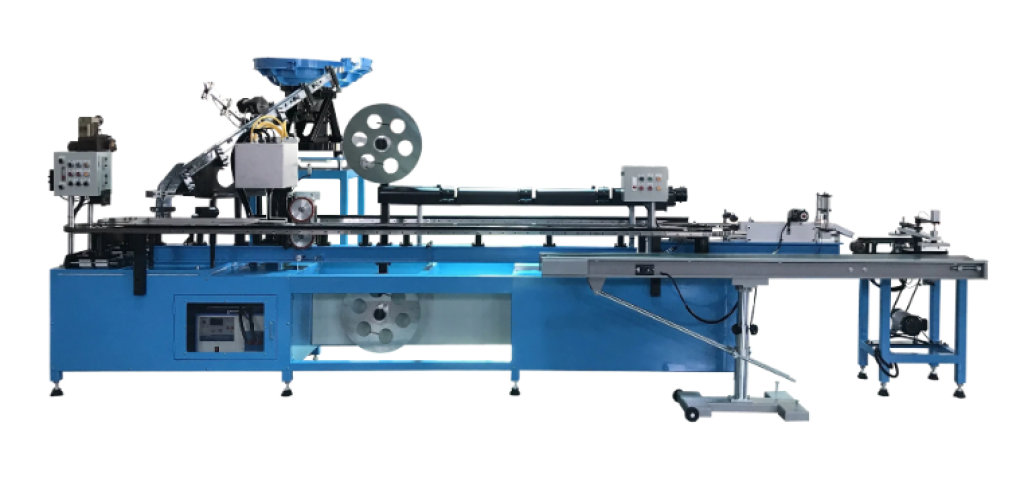

- Recommended Product: TICHO Wire Coil Nail Collator (15 DEG. WIRE COIL NAIL COLLATOR)

▲Our wire coil nail collators can produce 800 to 2200 nails per minute, speeding up the collating process.

2. Plastic Strip Nail Collator

Plastic strip collators connect nails in a straight row using sturdy plastic material. Modern plastic strip nail collators are capable of producing thousands of nails per minute. This type of collated nail is ideal for outdoor applications due to its resistance to wear and degradation under challenging conditions. Plastic strip nails offer strong holding power.

- Applications: Framing, sheathing, and general carpentry, particularly for outdoor work that needs sturdiness in various weather conditions.

- Recommended Product: TICHO Plastic Strip Nail Collator (21 DEG. PLASTIC STRIP NAIL COLLATOR)

▲ The 21-degree angle is a standard in many framing nails; K. TICHO Industries’s product ensures compatibility and ease of use in different nailing tasks.

3. Paper Strip Nail Collator

The paper strip nail collator uses paper tape to hold nails in a strip, ensuring even spacing and firm attachment for smooth feeding into nail guns. Its quick-decomposing paper tape is more eco-friendly than plastic. Besides, paper strips are easy to remove during use, creating a safer work environment with low waste.

- Applications: Primarily used with pneumatic nailing hammers for fast and profitable fastening of wooden structures.

- Recommended Product: TICHO Paper Strip Nail Collator (34 DEG. ROUND HEAD PAPER STRIP NAIL COLLATOR)

▲The machine can handle nail sizes ranging from 3.33 to 3.76 mm in diameter and 38 to 64 mm in length, making it suitable for various applications.