How to Select a Nail Collator

When choosing a nail collator, making the proper selection is crucial for maintaining the work rate in the operations. Below are the key factors to consider when buying a nail collator:

1. Production Requirements:

The first step is to understand your production needs. Consider the following:

- Nail Type: What types of nails will be used (e.g., coil nails, strip nails, paper-collated, or plastic-collated nails)? Head type and thread are also pivotal. Check if the machine is compatible with the type of nails.

- Material: Decide the material of the nails (e.g., stainless steel, aluminum, etc.) and check that the nail collator handles that material adequately.

- Nail Size and Dimensions: Verify that the nail collating machine accommodates the range of sizes (length and diameter) planned to process.

- Output Volume: Analyze the required manufacturing volume. If the demand is high, select a nail collating machine capable of producing nails for mass production.

2. Machine Performance:

The performance of the nail collating machine is one of the most critical factors to evaluate, as it directly affects manufacturing. Key performance indicators include:

- Speed: Check the nail collator’s operational speed, measured in nails per minute. Speedy machines are excellent for high-demand work, while slower ones may be more suitable for smaller batches. It’s also good if the machine has features like high-frequency inverter welders or automatic rubber banders.

- Accuracy & Stability: Verify the machine can collate nails consistently, lowering the risk of defective products.

- User-Friendliness: Evaluate whether the nail collating machine has an intuitive interface or control system, making it easy for staff to use with the littlest training.

3. Space Availability:

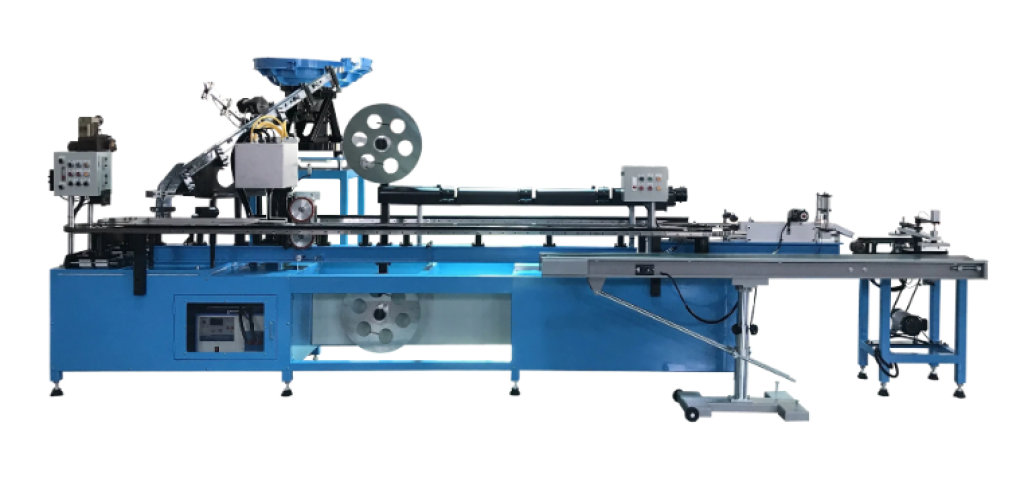

Before purchasing a nail collator, confirm the available space in the manufacturing facility. Nail collators come in various sizes, so it’s essential to choose one that fits comfortably within the workspace:

- Dimensions & Accessibility: Check that the area for the machine matches its footprint and has enough space around it for maintenance, refilling, and operator access.

4. Cost:

When selecting a machine, evaluate the initial expense versus long-term savings. Higher-priced machines may perform more tasks and last longer, making them a better investment. Don’t forget to include maintenance and replacement costs in your calculations.

5. After-Sales Support:

Dependable after-sales service is essential for smooth operations. Consider manufacturers who offer:

- Maintenance and Repair Services: Ensure the manufacturer offers timely maintenance services to avoid costly delays from unexpected machine downtime.

- Warranty: Look into the warranty details to find out what’s included and how long it lasts.

6. Manufacturer Reputation:

Choose a reputable manufacturer like K. TICHO Industries with a proven track record. K. TICHO Industries is a leading manufacturer with over four decades of experience in the fastening industry. We provide top-quality nail collating machines and are known for our exceptional customer service.